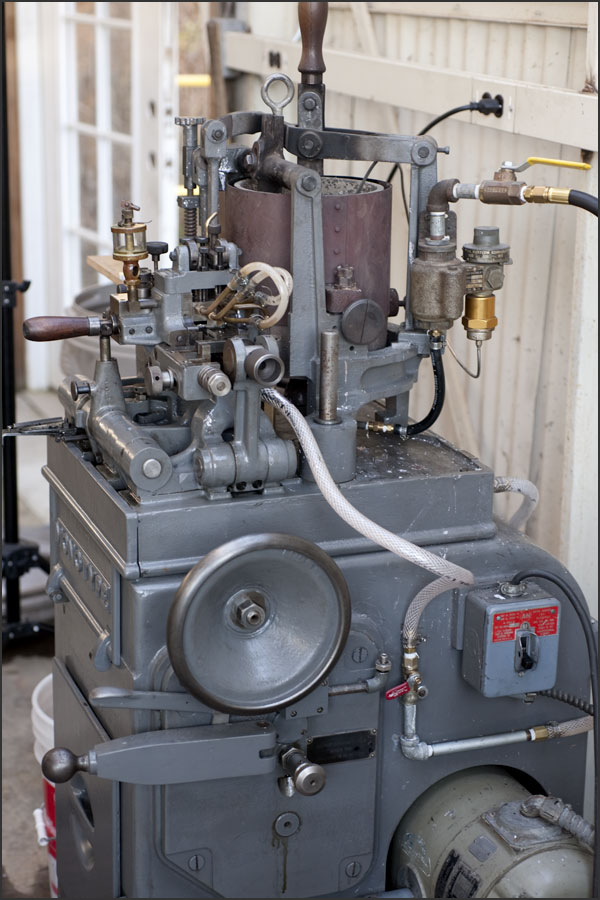

In October 2010 the Press acquired its own Monotype Thompson typecasting machine, along with dozens of series of matrices, the small recessed molds for the three-dimensional letterforms that are the essence of letterpress printing. Our Thompson caster will give us more control over the ‘fit’ and appearance of the types we use in our handmade books, and it opens up the possibility for designing our own typeface.

William learned the basics of Thompson Maintenance in Sky Shipley’s small workshop last year at the American Typefounders Association conference in Piqua, Ohio, and most of the 3-month restoration project went as planned. Our machine had not been used for over 20 years, and although it was in fairly good working order, the layers of grime, oil, and chipping paint invited a good cleaning and repainting before we put it back to work. First, the main mechanisms of the machine were disassembled, thoroughly cleaned, and painted again. The outdated gas-powered pot heater was converted to propane. A simple recirculating system was rigged to supply water to the cooling chambers inside the hot mold, and the electrical connections to the motor were modernized. Some parts in the critical nozzle mechanism had frozen and needed to be removed and replaced.

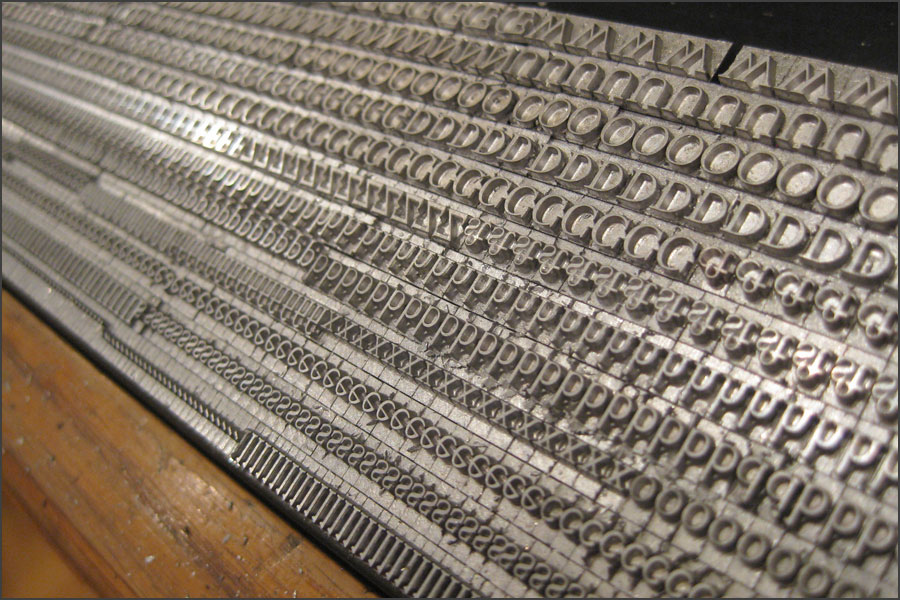

Meanwhile, Graciela and other volunteers were sorting and cataloging the matrices that came to us in old, disintegrating boxes, or worse, in loose piles. The matrices, mostly for commercial typefaces popular in the 1920s to 1950s, are now collected and labeled in newer, more convenient storage boxes.

After several days of careful adjustments and tests, the first usable type came marching out of the finishing ‘shoe’. The focus then shifted from learning how to restore the machine to learning how to operate it. Casting type on a Thompson caster is similar to playing a violin. The standard widths stamped on the matrices produce only average quality letter-fitting; sometimes the settings are just wrong. And although there is a small steel baseline standard to compare to, the baseline position is also not mechanically fixed. For best results, the position on the type body of each matrix must be manually set and adjusted in increments of less than .002 inches. With little to guide you but your eye and your experience.

We are now in the process of doing test castings of various fonts, to see which ones will suit our upcoming projects, and to gain the experience to cast each font correctly and to our own standards. And now we are in a good position to seek out matrices for those special typefaces we have always admired.